FLYING HIGH-FREQUENCY

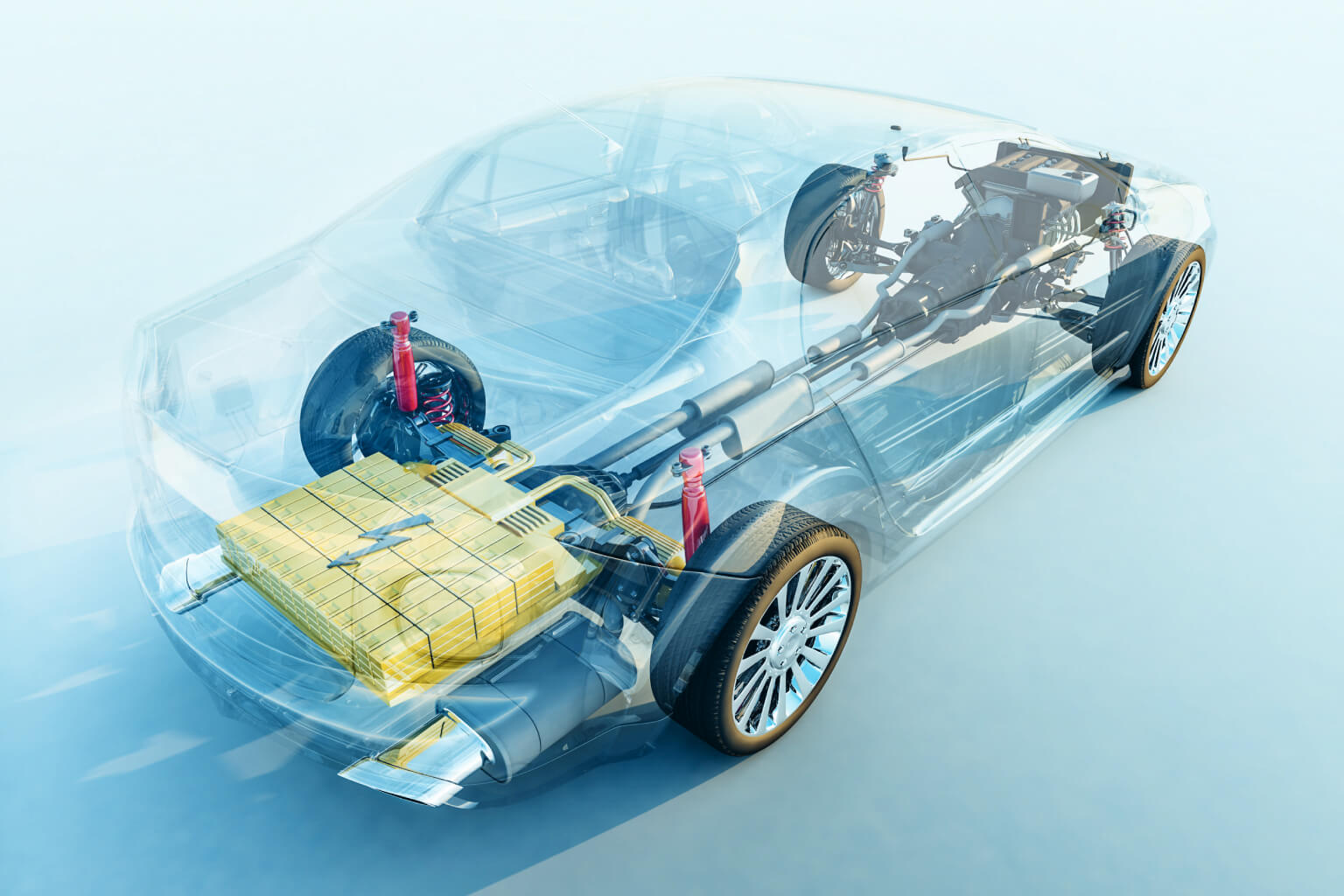

An Interview with Dr. Hans Hesse from Hesse Mechatronics The Paderborn-based specialist for ultrasound wire bonders and welding equipment is one of the world’s most successful providers in this field. With the company’s fully automated machines, high-precision electricity conducting connections can be established between semiconductors and the substrates they are on – for example, between high-frequency technology components, power electronics, medical technology, automotive technology or between cells in battery modules. The founder and CEO, Dr. Hans Hesse, gives us an insight into the more challenging times in his entrepreneurial career.

Dr. Hesse, how did you become an entrepreneur?

Looking back, I would say it was due to a series of lucky coincidences. As a young man, I’d often thought about setting up my own company, but I didn’t really know how to go about it. As an engineer, your focus is more on technical issues. And so, after receiving my doctorate, I went to work as a scientific assistant at the Robotics Research Institute at TU Dortmund University. Then a company asked me to develop a technological idea for a local streetcar company. The most complicated aspect of the task for me was writing an invoice – as a scientific officer. You could say that this was the start of my entrepreneurial career. After that I worked at the technical university during the day and the rest of my time was spent on my one-man business. But obviously nobody can keep that up for long. In 1988, with a big order on my desk, I gathered my courage and became fully independent.

Ultrasound welding equipment combines high speed with high precision.

Was this before you founded Hesse Mechatronics?

Yes, Hesse Mechatronics was only established in 1995. In the years before the company was founded, we took on various hardware and software service orders. The business slowly grew until we were commissioned to develop the controls for a bonder. That was our first contact with semiconductors. And this is what Hesse Mechatronics mainly deals with today. Our good luck at the time was that we already had a variation of the solution ready to go. Our bad luck was that the customer went bust before they could pay.

Dr. Hans Hesse

Hans Hesse is the founder and managing director of Hesse GmbH, Paderborn. After studying physics at the University of Münster and electrical engineering at Ruhr University Bochum, he worked as a scientific assistant at the University of Hagen and received a doctorate in electrical engineering. He left his post on the academic board of the Robotics Research Institute at TU Dortmund University to start his own business in 1988. Find out more at: www.hesse-mechatronics.com

So this turned out to be the first real crisis you faced?

And luckily we made it through. We had already put so much work into the project, that I could not give up on it. I had a contact in business development and this contact led me to a KfW development bank subsidiary in Bonn where we received funding of two million deutsche marks. A customer from our home region of Ostwestfalen made this step possible for us. The entrepreneur was impressed with our idea and became the project’s lead investor

A central component of an automatic bonder is the electro-mechanical transducer, which makes a tool generate bending vibrations. The tool, which looks like a needle, pushes a wire onto the contact and vibrates back and forth at a frequenzy of 100kHz (100.000 vibrations per second) for example, and with an amplitude of a few micrometers (a few thousandths of a millimeter). Using a friction welding process, this allows a conductive connection to be created within a thousandths of a second.

So with the development bank and the entrepreneur, there were already two who believed in you and your project …

Yes, and this was especially important in the beginning. Looking back, I’d say we were also quite naive. I began the development of our machines thinking that we just had to give our customers the right kinematics – or to put it more simply, motion mechanics – with sufficient precision and dynamics. It was the customers themselves who were the experts in the technology this would build on. So I wrongly assumed that we would just have to purchase the central component, the electromechanical transducer. But as soon as the first machine was ready, I saw that I was mistaken.

And so you had to take on this task, too?

For better or worse, because there was no going back. If I had known this to begin with, I would probably never have developed the bonder – the job would have been too daunting. So in retrospect, my lack of knowledge was an important part of what gave me the courage to take on the task. When young entrepreneurs present their ideas to me nowadays, I sometimes recognize this same appetite for adventure, which will help them to overcome some of the obstacles they may face in the future.

Battery technology is one of the many application areas where bonders and smart welders are used.

An entrepreneur’s path also has some surprises then. Did it always end well in your case?

Let’s just say there weren’t only surprises of a technical nature. Surprises can pop up in all areas of life and their effects can be very different. But whatever happens, entrepreneurs need a certain amount of resilience. For example, I once discovered that a business partner had been cheating me for years. In these critical situations it takes a lot of strength to fight back. On the other hand, you need space to switch off and recharge. You also need people that you can trust and ask for advice. The path that an entrepreneur walks can be very narrow – but, to answer your question, in the end there was always a solution to every problem.

Having someone you can trust is important. Would you say this also applies when it comes to developing new ideas?

Definitely. Marketable innovations come about when we combine different perspectives. I like to exchange ideas with Prof. Wallaschek, for instance, whom we have been working with for more than 25 years. He heads the Institute of Dynamics and Vibration Research at the University of Hanover. Our customers, too, are important partners for me and the company when it comes to brainstorming new developments. Our discussions with them give us very specific trigger points that we can use in developing and improving our products. Of course, this only works when both sides trust one another. Without trust you hit a wall of silence. We have gained this trust, broken through the wall and created an atmosphere of cooperation based on trust.

Do you sometimes worry that you are missing important innovations?

As specialists, we’re active in a very small market that we know well. We only have one competitor in Germany. Beyond that there are another three to five worldwide. However, in these fast-changing times, we are in no way protected against surprises. That is why we also cooperate with universities and large companies in the electronics industry, in addition to our own innovation work. As a leading company in the market, we are always under pressure to be at the right place at the right time with the right machine. We take this challenge on every day.

Hesse Mechatronics currently employs around 220 employees in Germany, Hong Kong, Japan and the United States. The headquarters at Lise-Meitner-Straße, completed just three years ago, are now undergoing another several-million-euro expansion.