[IN]side INTRODUCING INDUS PROJECTS

MIKROP – Good things come in tiny packages – miniturized plastic single use optical devices

THE STARTING POINT

As a manufacturer of high-precision miniaturized individual lenses and lens systems, particularly for use in medical technology, endoscopy has been a very strong business area for the INDUS portfolio company MIKROP for a number of years. Reuse of the instruments for minimally invasive operations is standard. But when it comes to flexible endoscopes in particular, as used, for instance, in colonoscopies, gastrointestinal tract endoscopies, or – as often required for COVID-19 patients – bronchoscopies, bacteria can colonize the channels, despite exhaustive sterilization following the operation. This means there is a threat of cross-contamination, as diseases can be spread via contaminated instruments. This is a threat that must be taken seriously, especially in light of multi-resistant germs.

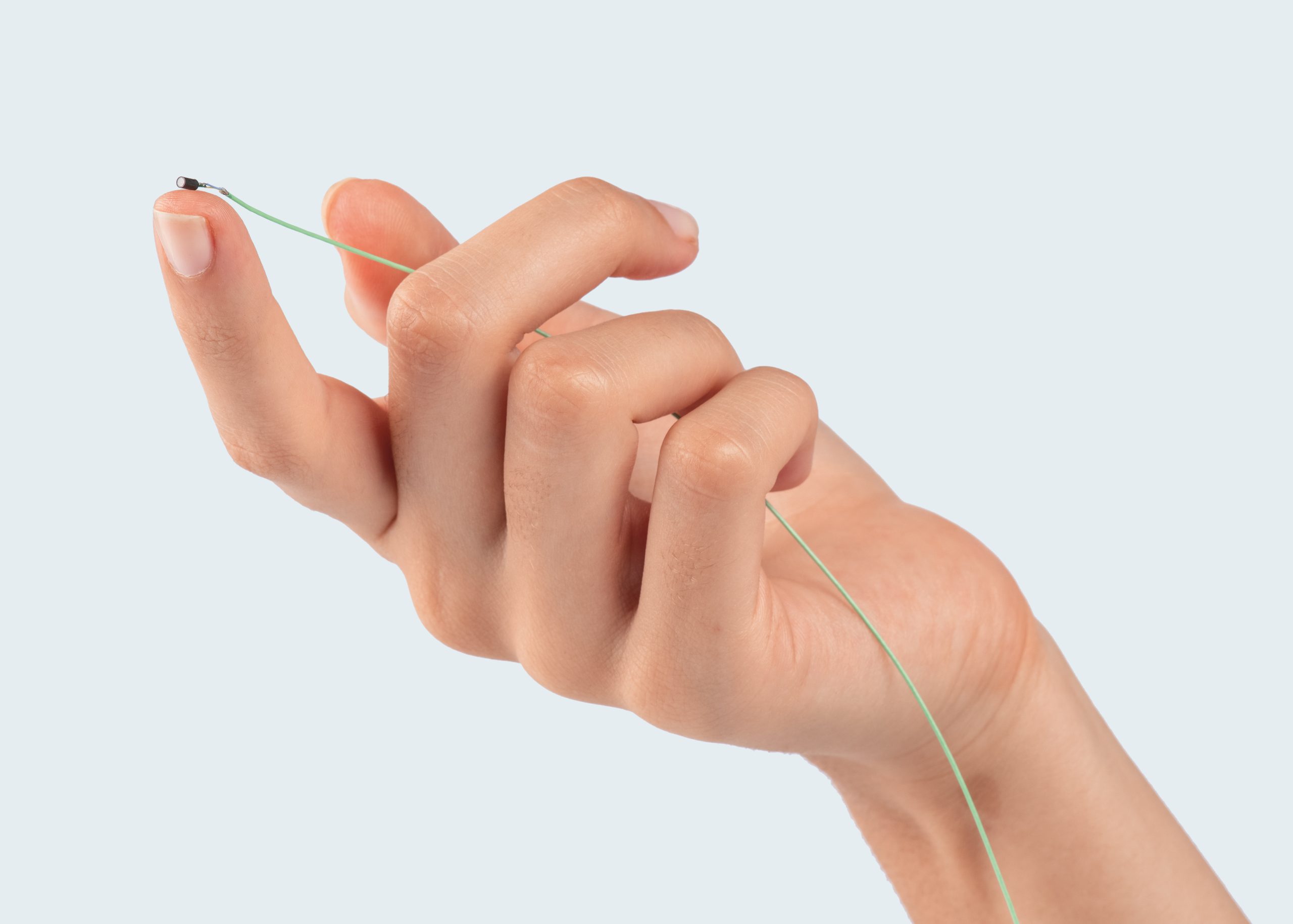

The plastic MIKROP lenses built into a microcamera have a diameter of just 1 mm.

THE SOLUTION

Single-use endoscopes may be an answer. Single use of sterilized instruments minimizes the risk of cross-contamination through equipment. And there are no costs for endoscope preparation and repairs.

THE CHALLENGE

The manufacturing process plays a decisive role when it comes to transitioning microlenses to single use. The traditional production processes for glass optics for single use – and the volumes this requires – are simply too expensive. Plastic lenses, as used in smartphones with a diameter of 5 to 8 mm, produced using the cheaper injection molding process are too large for medical use.

THE PRODUCT

The MIKROP team, supported by the INDUS innovation development bank, has been working on developing high-precision plastic micro-objectives since 2019 – with great success. The demo product delivers the same image quality as glass optics – with a lens diameter of just 1 mm. The manufacturing process also enables the production of more complex lens geometries due to cleverly designed forms. Aspheric lens shapes mean the number of lenses can be halved – a clear efficiency advantage. This new type of lens, which can be individually customized, is also suitable for industrial applications. Another advantage is that the single-use prototypes were built as chip-in-tip systems. With this innovative approach, the image is recorded directly in the tip of the endoscope using an image sensor and digitally transmitted.

The free form of the new optical devices enables very high image quality with maximum depth of field.

THE OUTLOOK

As part of this successful project, MIKROP has expanded its development expertise with an innovation team headed up by Chris Jung. Plans for the next steps are already in place. MIKROP will build up its internal coating expertise both at the Swiss headquarters and at the production facility in Kać, Serbia. All ready for the next innovation.

BETOMAX AND IMECO – Introducing lean management

MORE EFFICIENT, MORE EFFECTIVE, BETTER

If you want to grow as a company, it is important to be in control of your processes and carry out regular checks. Sounds simple – but process optimization is not always as simple as it sounds. “Old” working methods and mindsets, a lack of resources and insufficient knowledge can all get in the way.

INDUS Group companies have it a little easier because they have the support of the holding company through the strategic initiative “Improving performance.” INDUS supports important development projects, investments and change projects. Not just financially, but also with the right expertise. One of our experts is Dr. Torben Schmitz. Among his other talents, he offers the portfolio companies comprehensive training and development support in the area of lean management.

What is lean management exactly?

Lean management is a method to constantly improve processes and covers the efficient and effective design of the entire value chain. The main aim of this approach is to identify and prevent potential wastefulness in all corporate areas. A variety of lean techniques are used to achieve this, such as the 3M or 5S methodologies, or the PDCA cycle. The lean techniques enable the transparent depiction of complex connections and processes so that weak spots and potential can be identified. The main focal points of the approach are customer orientation and cost reduction.

BETOMAX – ON THE ROAD TO LEAN MANAGEMENT

BETOMAX is one of the INDUS companies that has introduced lean management with the help of Dr. Torben Schmitz and further experts from Aachen University’s machine tool laboratory. During the training courses, employees from the concrete construction specialist company got to grips with the far-reaching aspects of lean management. The decision to set up a lean administration was made quickly.

In 2021, processes were examined and weak points in administration and in the handover from sales to production were uncovered. The findings now have to be specifically addressed. A project to introduce lean administration will be launched at the beginning of 2022. The BETOMAX employees who have already been trained as lean officers will be closely involved in implementing lean administration processes.

IMECO – PRODUCTION OPTIMIZED

The INDUS subsidiary IMECO, a certified manufacturer of medical devices in Goldbach, is also convinced that process optimization is a key success factor when it comes to improving competitiveness. Lean management has been rolled out at the plants in Germany and Poland over the course of the last year and a half. To facilitate this, five IMECO employees were given training by the INDUS holding company. With INDUS’ support, the company launched the project with a process analysis at the beginning of 2020. Weak points were identified and lean options to optimize these were then selected.

Following the analyses, lean management was rolled out to the individual facilities and training courses were offered for employees and managers. The training courses covered topics such as the lean management principles, the 5S methodology and shop floor management. The participants now implement what they learned and their new ideas into their everyday work. The final objective is to significantly reduce lead times.

HORNGROUP – MYTECALEMIT – Software as a service

DEVELOPMENT OF “MYTECALEMIT” SOFTWARE

TECALEMIT is a specialist for products and services relating to refueling and measuring fuels. TECALEMIT’s digital success story began in 2018 with the “myTecalemit” cloud solution project.

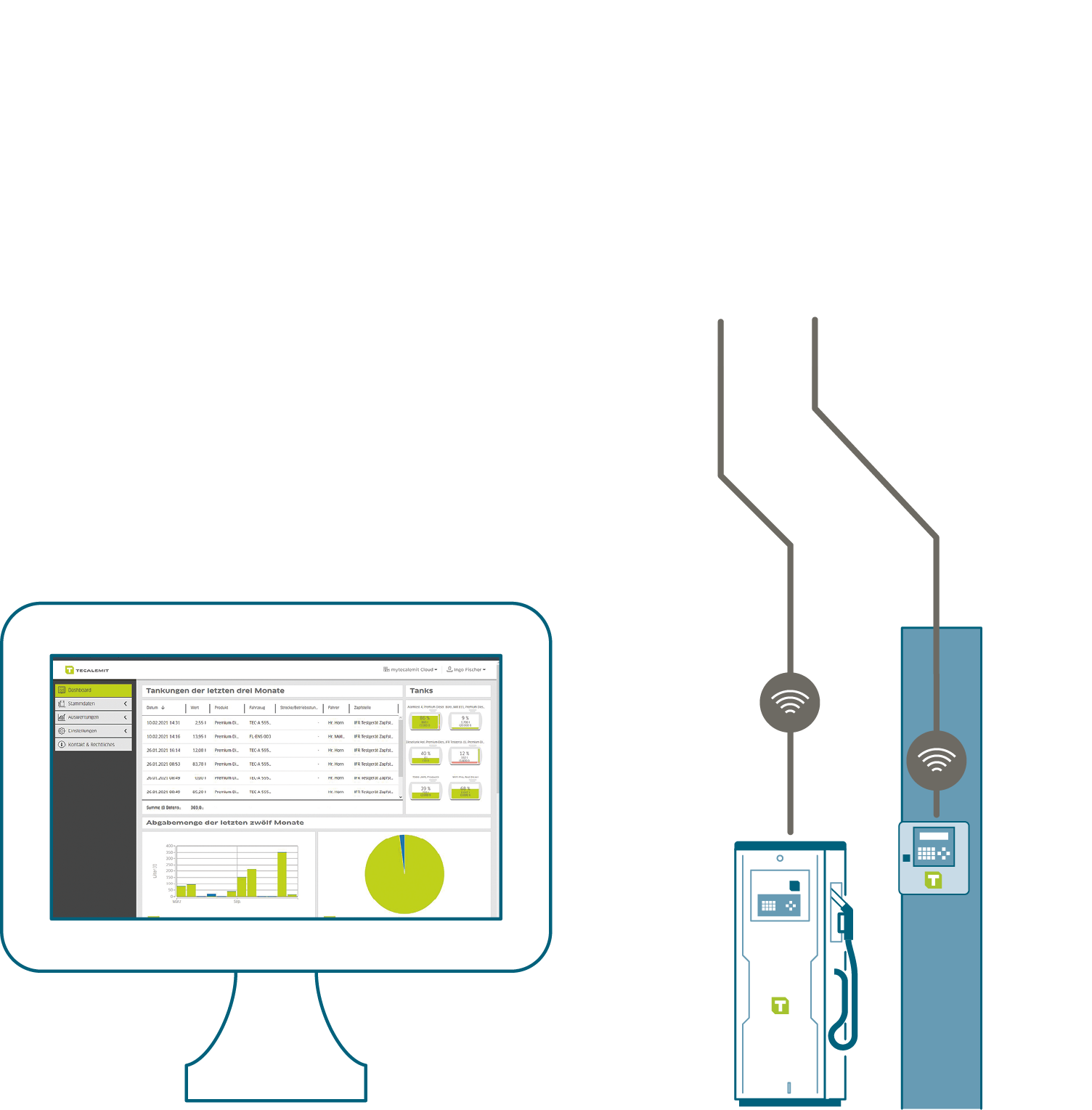

The Flensburg-based company developed a web-based tank data management system that can run on any end device called “myTecalemit.” The cloud project was supported by the INDUS innovation development bank. TECALEMIT customers can now access a detailed analysis of their tank data, such as fill levels and refueling procedures, anywhere and at any time. In addition to the analysis options, customers are also offered real added value with access control and fully automated reordering of fuels.

Find out more in the [2019] Magazine on p. 18 et seq.

SOPHISTICATED CLOUD SOLUTIONS

Supported by the INDUS initiative to promote portfolio companies’ market excellence, the HORNGROUP adopted its new corporate strategy “HORN Flensburg 2025” last year – laying the foundation for 15 subprojects aimed at achieving the company’s strategic realignment.

The enhancement of “myTecalemit” was identified as a promising subproject. Once the software is successfully established on the market, the cloud application’s licensing and distribution model will be expanded as part of the project. “Software as a service” is the key approach here. This is aimed at responding to customer needs and user behavior. TECALEMIT is transitioning to a tiered subscription model allowing customers to choose the tier that best suits their requirements.

And the next innovative project is already waiting in the wings. The smart meter is a stationary bulk electricity meter with a variety of control options connected to the cloud solution. “myTecalemit” software is enjoying all-round success with its scalability – presenting a constant stream of new opportunities.